Looking at Spectrum Laser Australia: New Ideas in Precision Engineering

Spectrum Laser Australia is one of the most well-known organisations in the field of precision engineering. They are changing the game in advanced manufacturing by being dedicated to innovation and excellence. This powerful Australian company uses the latest laser technology to provide quality and accuracy that no one else can match in a wide range of fields.

Their knowledge is generating ripples in many fields, from aerospace to medical gadgets. Industries encounter new problems as they change. Spectrum Laser not only faces these problems head-on, but it also comes up with new ways to fulfil future needs. Let’s look more closely at the technologies that make them different and see how their new ideas might help your projects reach new heights.

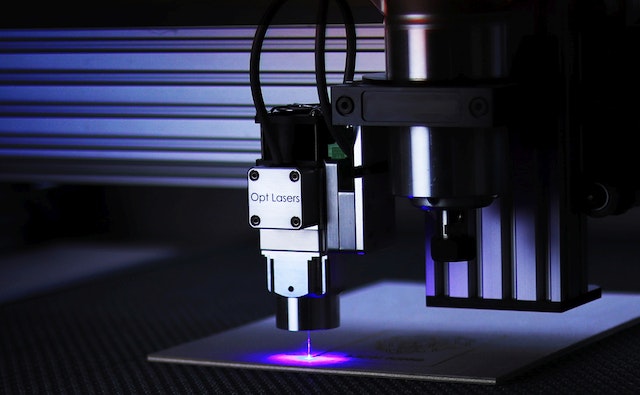

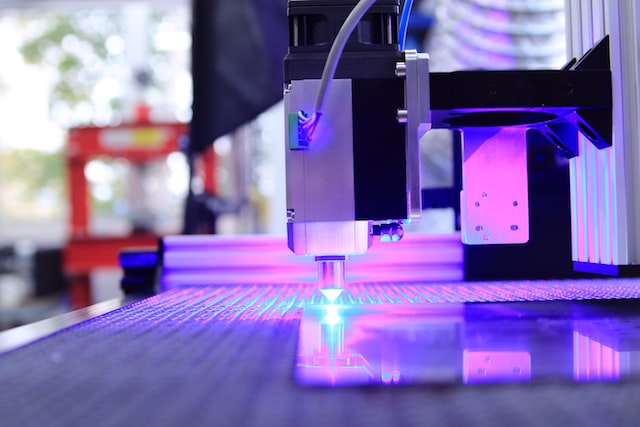

The Technology That Makes Precision Engineering Possible

The spectrum laser uses modern laser equipment that can cut and engrave with high resolution. This technology makes sure that every detail is done with perfect accuracy.

Software integration is at the heart of their new ideas. Advanced algorithms improve how machines work and let them make changes in real time while they are running. What happened? Outputs that are perfect and meet all of the client’s requirements.

Automation is also very important for efficiency. Automated processes cut down on mistakes made by people and boost productivity. This level of reliability becomes necessary as industries change.

Spectrum Laser additionally uses high-quality materials to make their devices work better. Each part is carefully chosen to make sure it lasts and works well even in tough conditions.

With these kinds of improvements, the field of precision engineering keeps changing, opening up endless possibilities for use in many different fields.

How Spectrum Laser’s New Ideas Can Be Used

Spectrum Laser’s new ideas are useful in many different fields. In the automotive industry, precise cutting and engraving improve the design of vehicles while making sure they are structurally sound. This technology lets you add fine details that current customers like.

The aircraft industry also gains a lot from this. Parts made with laser precision provide the best performance in high-stakes situations. Every ounce of weight counts here, thus Spectrum’s solutions are highly useful.

These new technologies also work quite well in the field of medical equipment. Customisation and precision are very important for implants and surgical equipment, which improves patient outcomes.

In addition, the arts and crafts sector uses Spectrum’s technology to make things that are unique to them. Artists can make amazing effects on a wide range of materials, from wood to metal, turning commonplace things into amazing works of art.

Spectrum Laser is clearly changing many landscapes with its innovative technical processes, given how flexible they are. Every application provides a story of how new ideas may meet real-world demands without any problems.

Why You Should Choose Spectrum Laser for Your Engineering Needs

There are several benefits to choosing Spectrum Laser Australia for your engineering projects. First and foremost, its cutting-edge technology ensures accuracy that is unsurpassed in the field. Every machine is made to provide you the same high-quality results every time, so you always get what you need.

Spectrum Laser also takes pride in its dedication to coming up with new ideas. They are always making their products and processes better, which means that customers get the best new laser technology. This helps firms stay competitive and get things done quickly.

The ability to customise is another important benefit. Spectrum Laser knows that every project is different, thus they offer customised solutions to match your needs. Companies can be more creative because of this freedom, but they can still get things done with great accuracy.

Customer service is also very important at Spectrum Laser. Their staff is made up of experts that are ready to help you with every step of your project, from the first meeting to the last delivery. This will make sure that everything goes smoothly from start to finish.

Working with Spectrum Laser can help you save a lot of money over time because their production procedures are more efficient and waste less. When you choose them as a partner for your precision engineering needs, you’re not only getting high-quality work, but you’re also making sure that your business will be worth more in the long run.